Site Operating Plan

Site Operating Plan

Having a good site operating plan can increase efficiency, output, and safety on a renewable energy site. We incorporate these measures and other important goals into our approach as we plan out the different aspects of running the business. Some of these factors include…

- Risk Management

- Safety

- Resource Allocation

- Ecological Strategy

- Regulations

- Communication Strategies

- Legal Requirements

- Quality Assurance

Our site operating plans provide a roadmap that helps maneuver projects to the solutions they need. The complexities of renewable energy sites can be daunting, but we can help lay down the foundation for success.

Site Operating Plan (SOP) Benefits

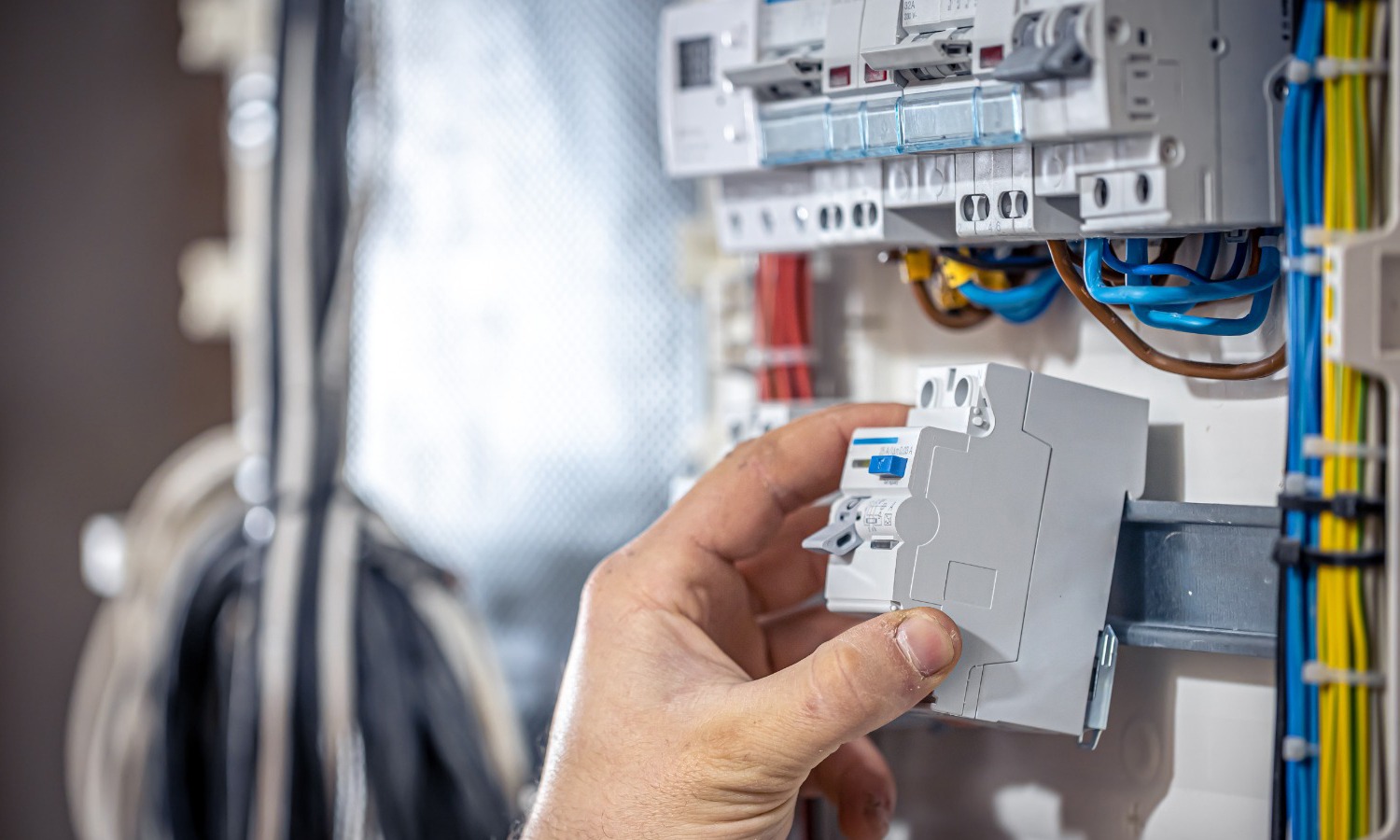

Businesses that utilize a site operating plan (SOP) are better prepared to achieve company objectives and overcome obstacles. This includes ensuring that a work environment is efficiently run, better able to handle risks, operates within a budget, and is, above all, safe. An SOP manual is a comprehensive operating and maintenance (O&M) manual specific to each facility.

Overview of the SOP

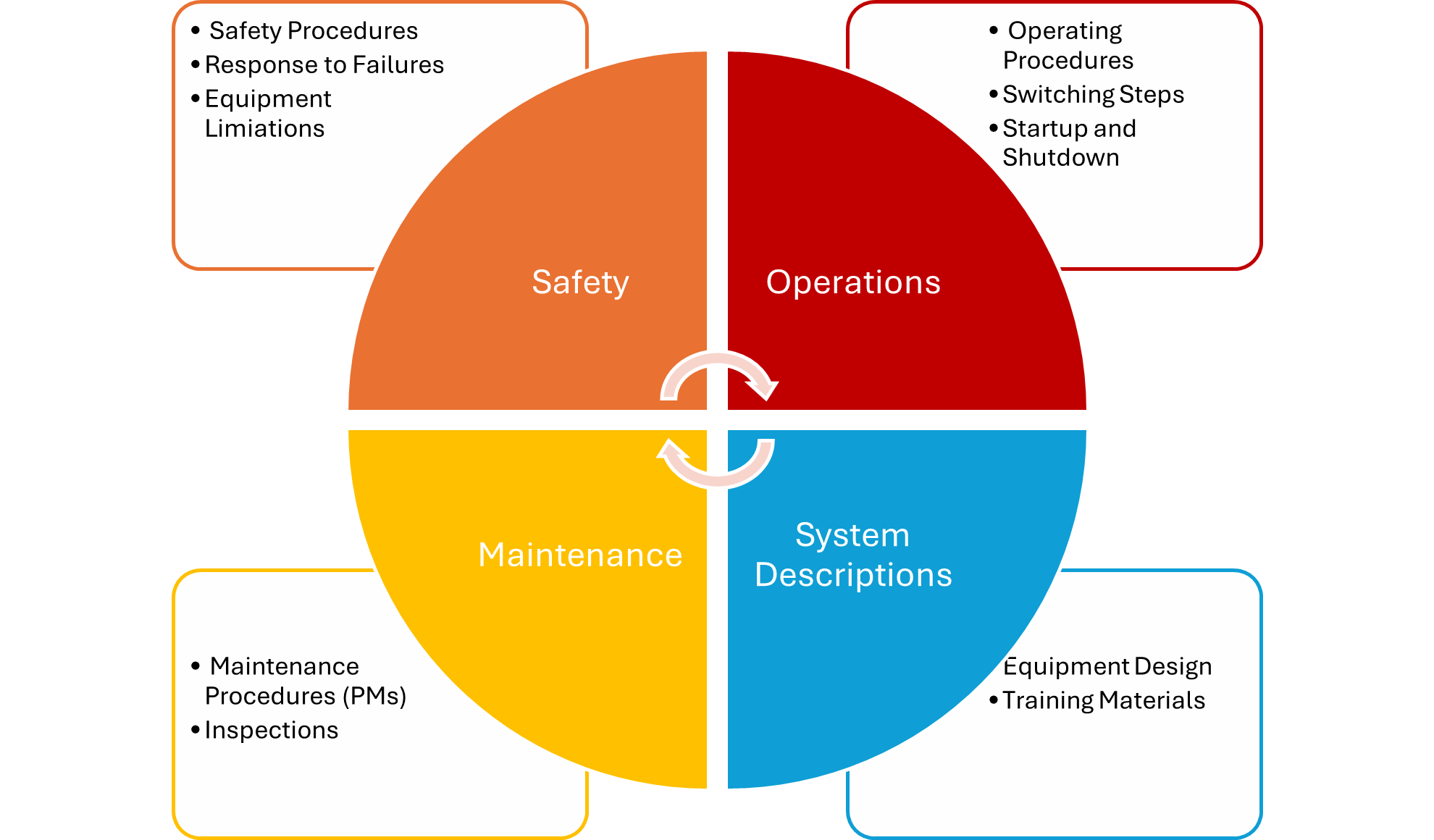

Our primary focus when assessing any new site is safety. Therefore, that is what we start with when we begin a site operating plan for a client. In our assessment, we include different safety measures such as varying safety procedures, failure response plans, failure response times, and equipment limitations. Then, we move on to operating measures of the business to build on operating procedures, switching steps, as well as startup and shutdown procedures. Next, systems are assessed with different descriptions concerning equipment design and training materials. Lastly, to ensure things continue to run smoothly for the facilities, maintenance measures are considered which include maintenance procedures and inspections of facilities/materials.

Safety Measures

Safety Procedures, Response to Failures, Equipment Limitations

Operating Measures

Operating Procedures, Switching Steps, Startup and Shutdown

System Measures

Equipment Design, Training Materials

Maintenance Measures

Maintenance Procedures (PMs), Inspections